Industry Knowledge Exhibition

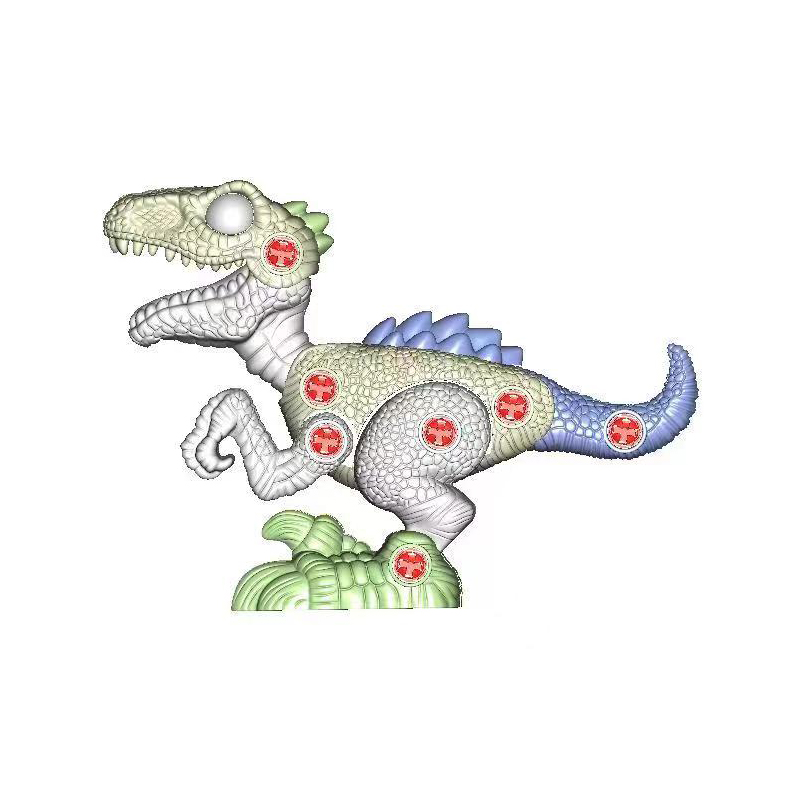

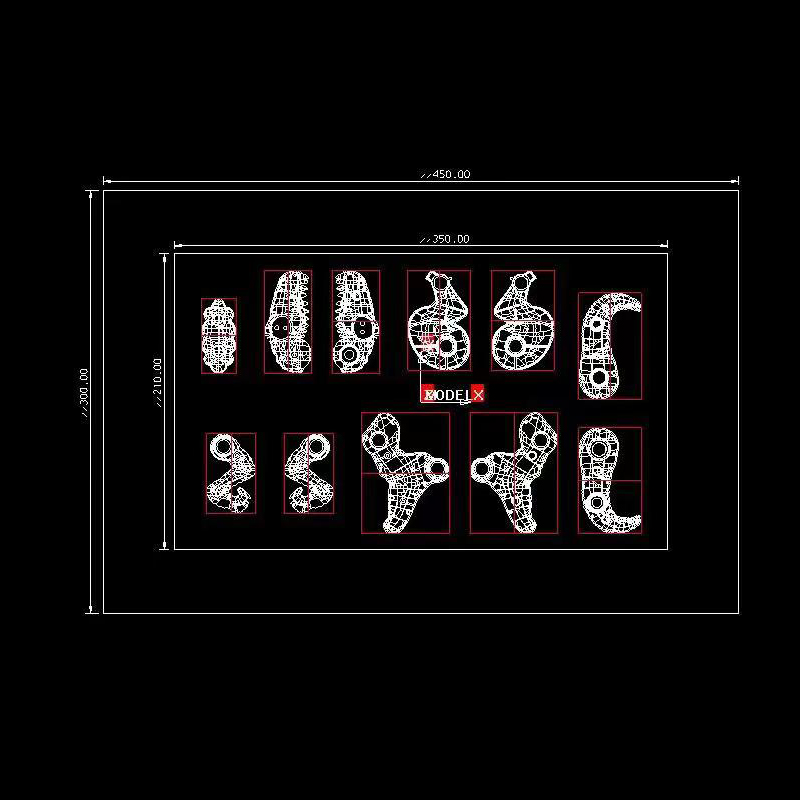

Application of Plastic Dinosaur Toy Injection Mould

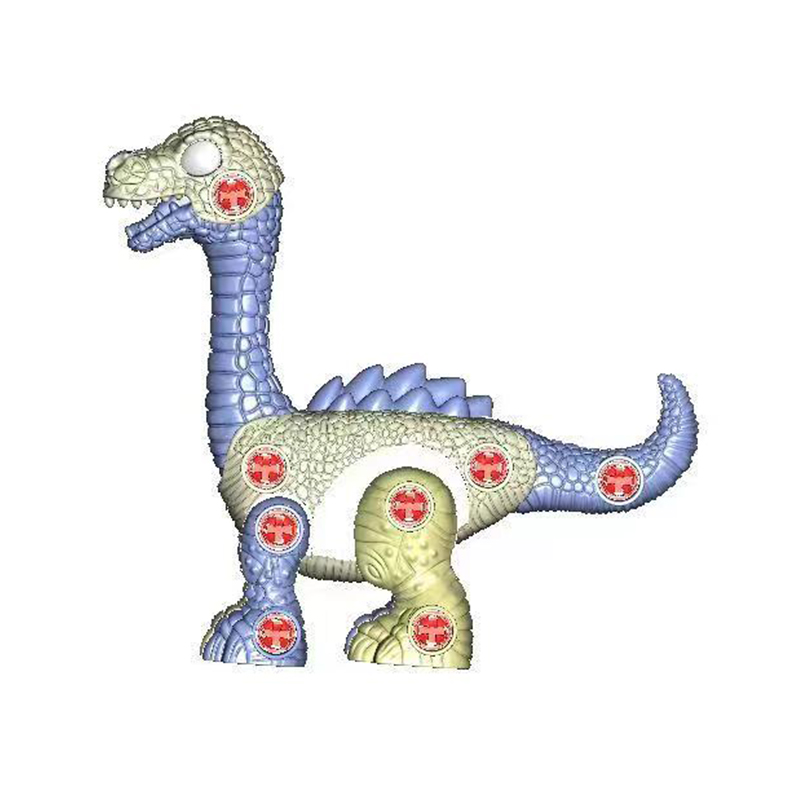

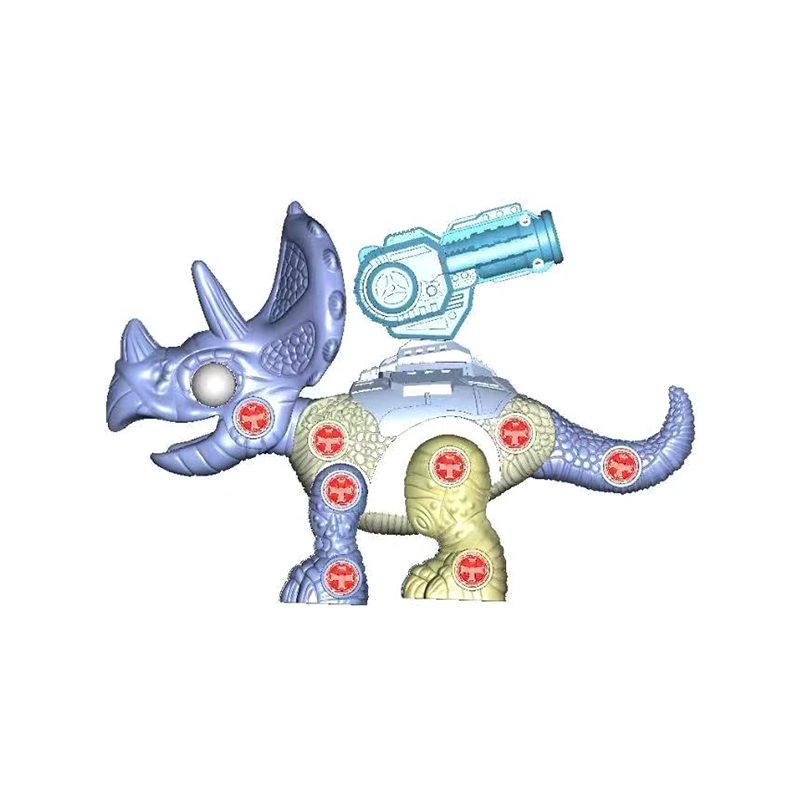

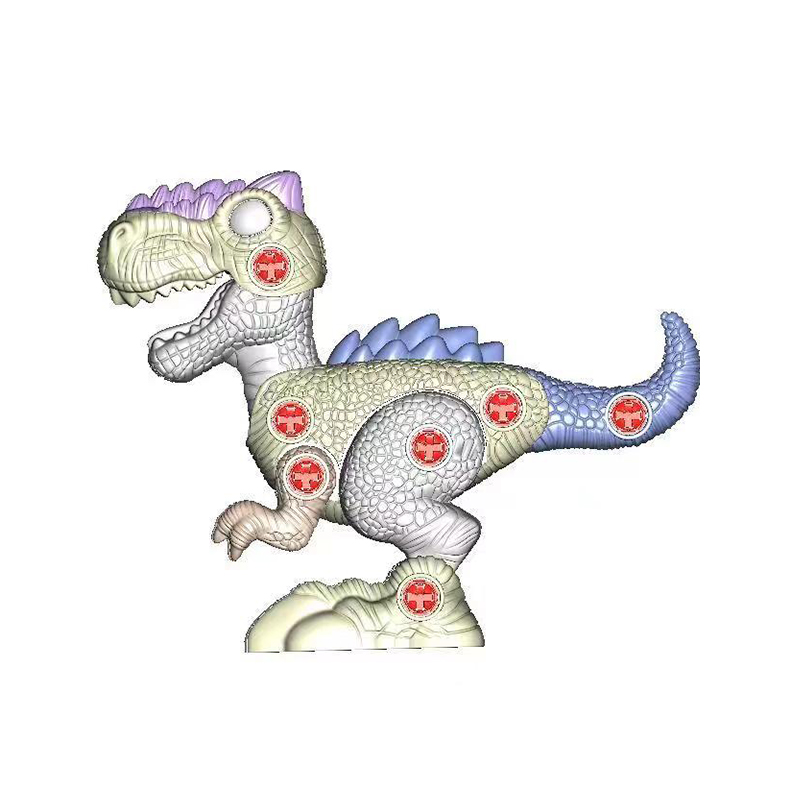

Plastic dinosaur toy injection mould have become a significant component in the toy manufacturing industry. These mould are essential for producing intricate and detailed dinosaur figures that captivate children and collectors alike. A plastic dinosaur toy injection mould supplier plays a pivotal role in this process by providing the tools necessary to create these engaging products.

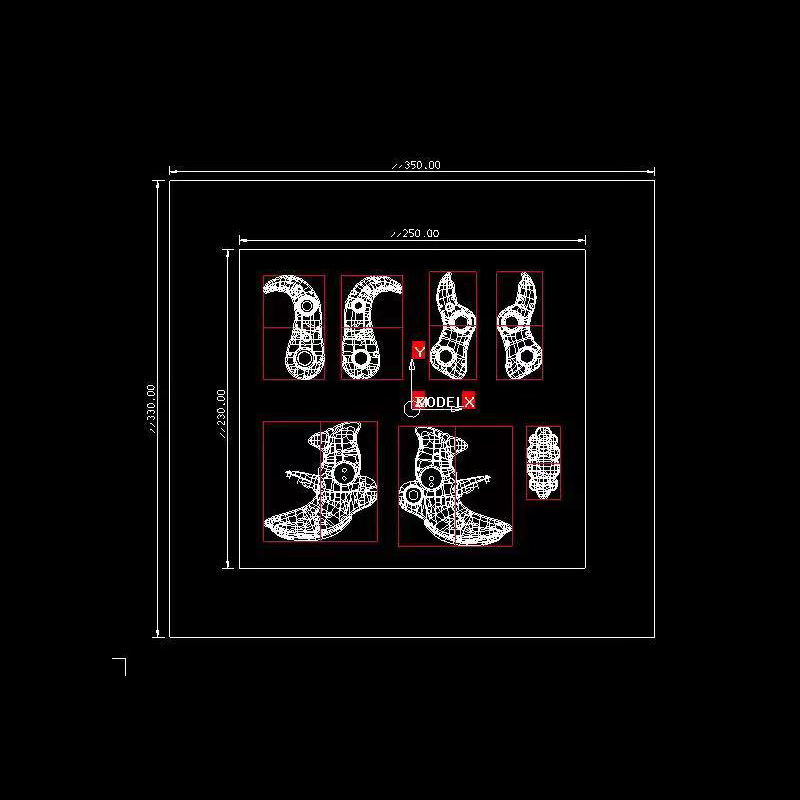

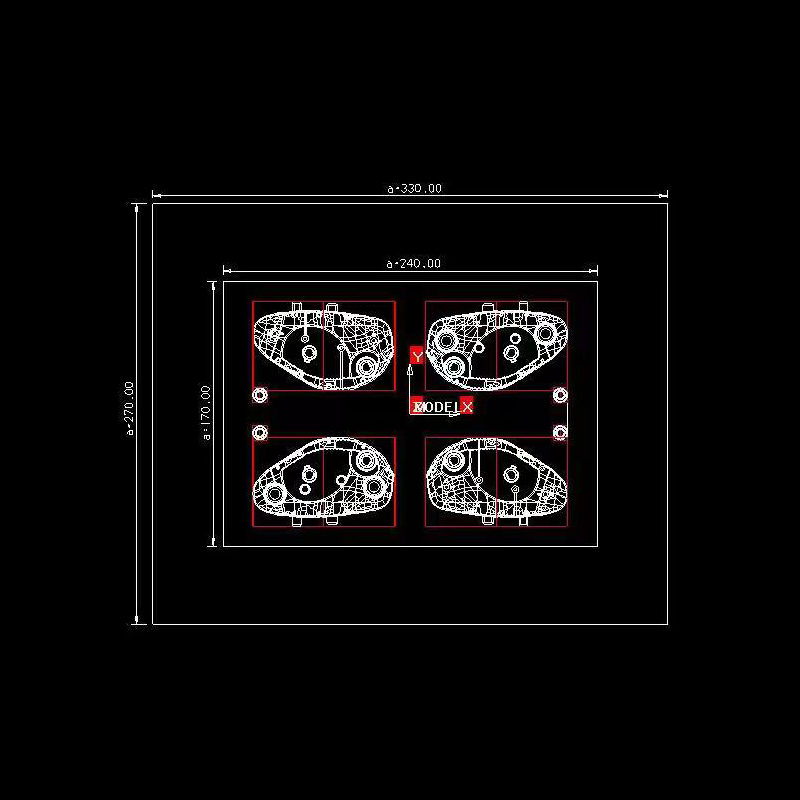

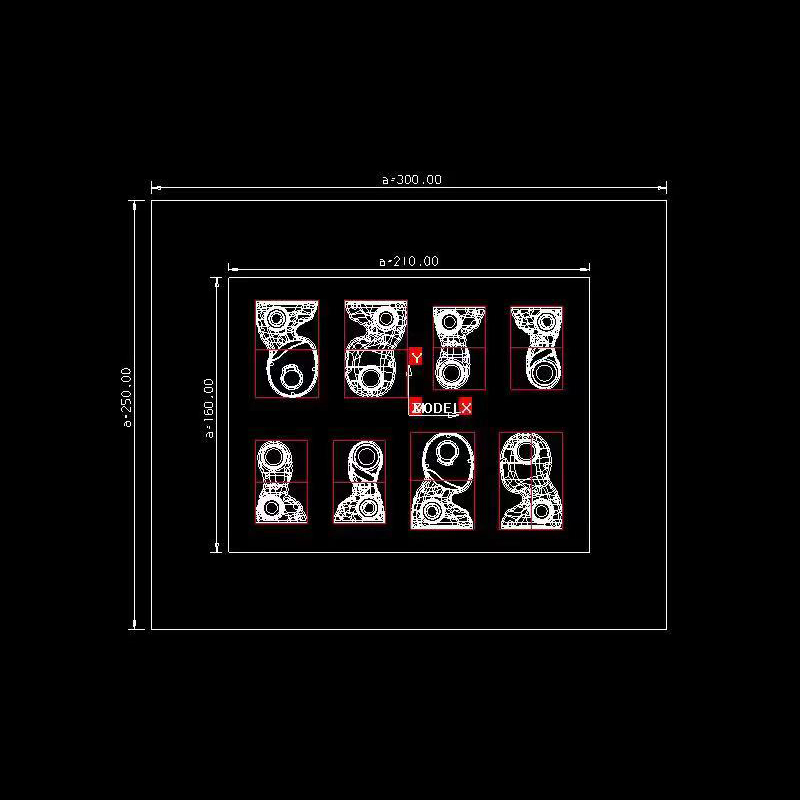

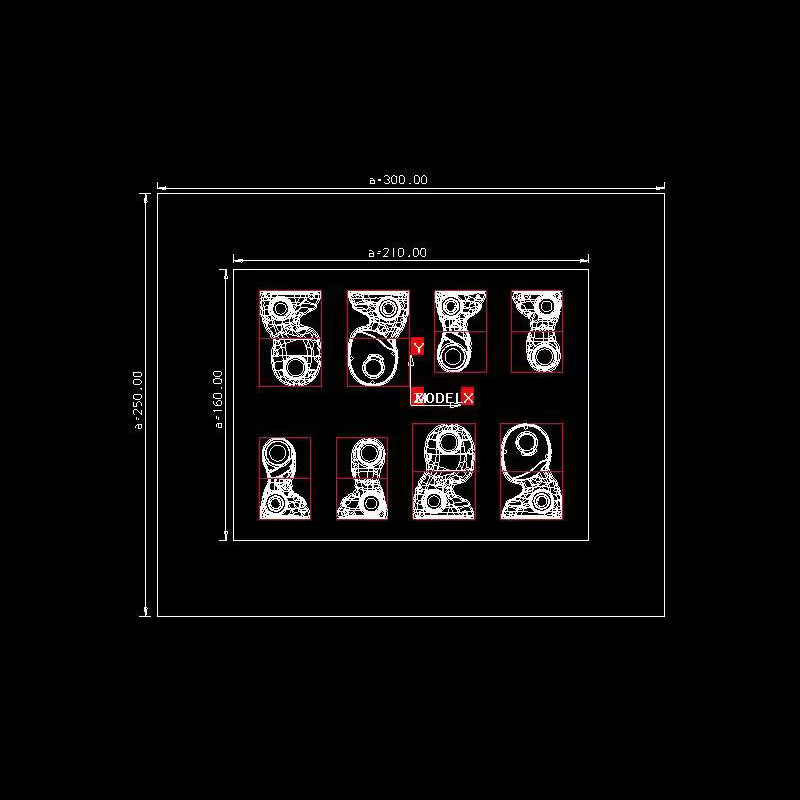

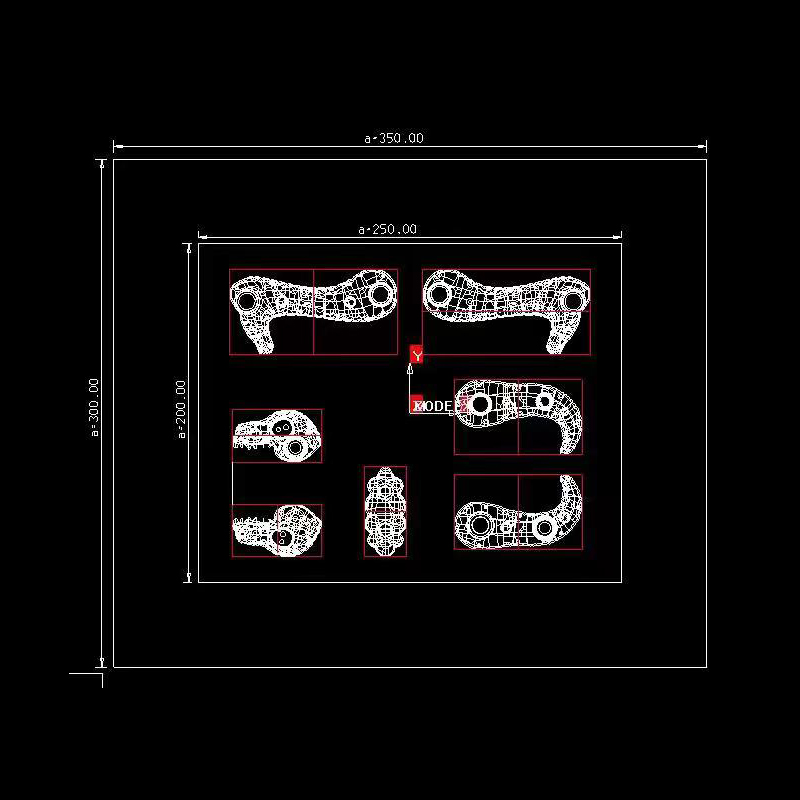

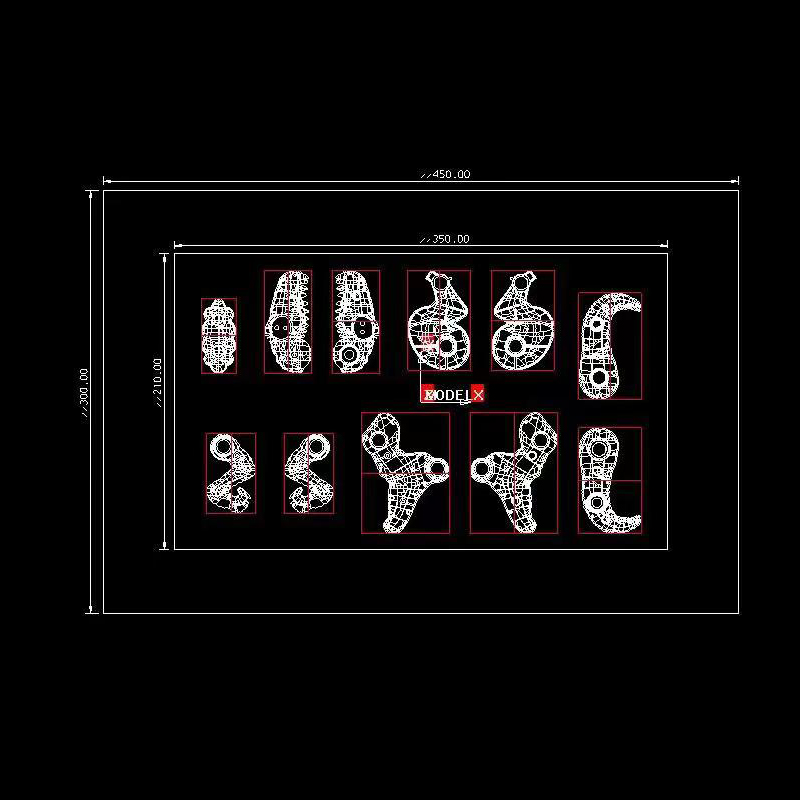

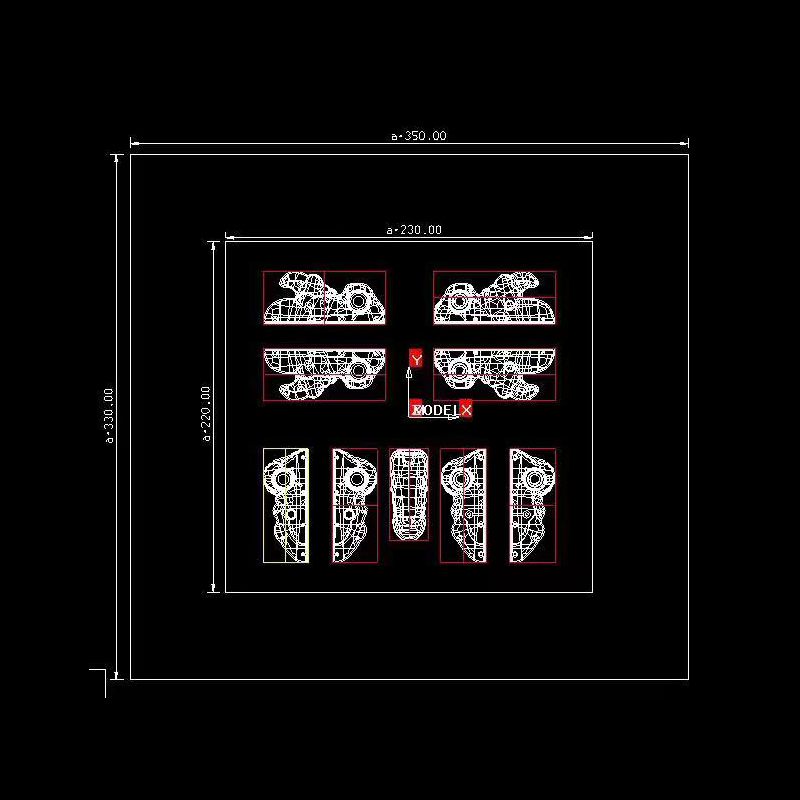

The application of Plastic Dinosaur Toy Injection Mould Supplier involves injecting molten plastic into a specially designed mould to form dinosaur shapes. This process allows for high precision and consistency, ensuring that each toy meets the desired specifications. The mould are crafted to include fine details that bring the dinosaur figures to life, from scales and textures to realistic postures.

A plastic dinosaur toy injection mould supplier typically offers a range of mould designs tailored to various dinosaur species and toy sizes. This versatility supports the production of diverse toy lines, catering to different market preferences. Additionally, these suppliers often provide expertise in mould designs for efficiency and cost-effectiveness, helping manufacturers streamline their production processes.

The use of Plastic Dinosaur Toy Injection Mould Supplier also contributes to durability. The plastic used in this mould is selected for its resilience, ensuring that the finished toys can withstand regular handling and play. This durability is crucial for maintaining the quality and safety of the toys, which are often subject to rigorous testing.

Overall, the application of Plastic Dinosaur Toy Injection Mould Supplier is integral to creating engaging and high-quality toys. By partnering with a reliable plastic dinosaur toy injection mould supplier, manufacturers can ensure the successful production of these popular and cherished items.

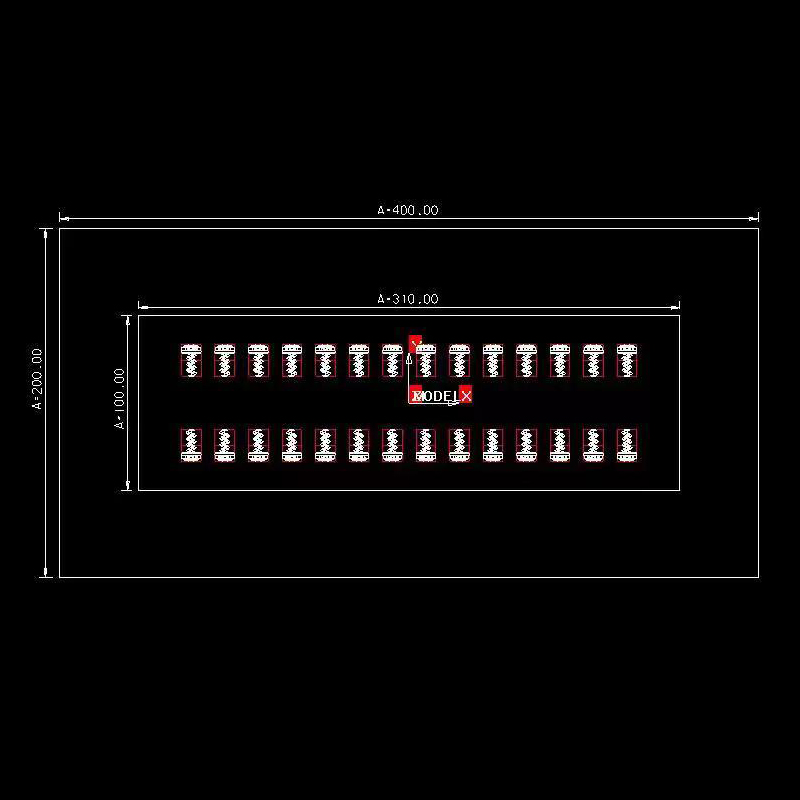

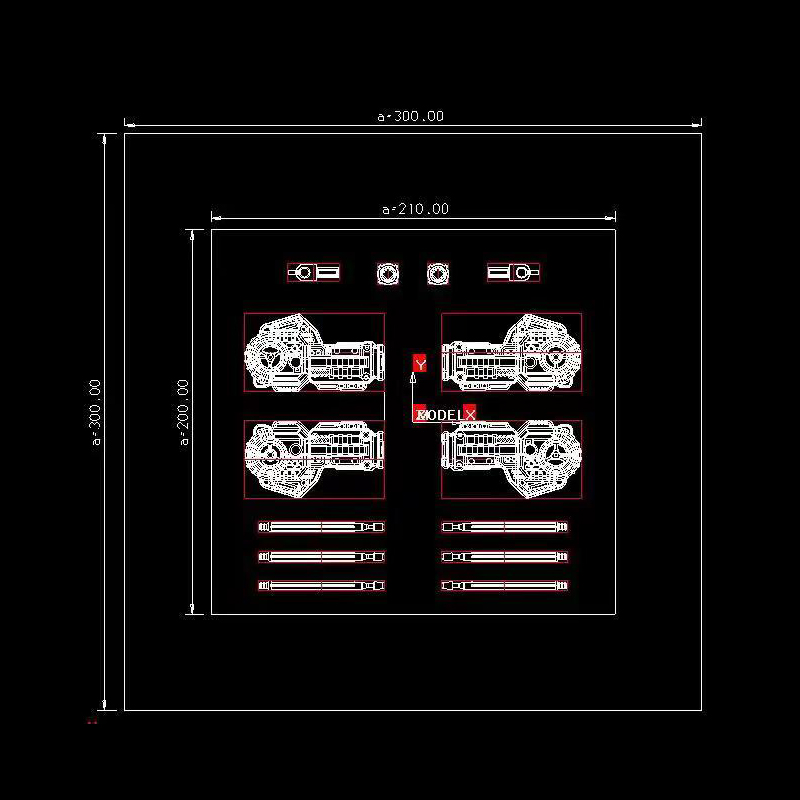

Advantages of High-Quality OEM Plastic Mould

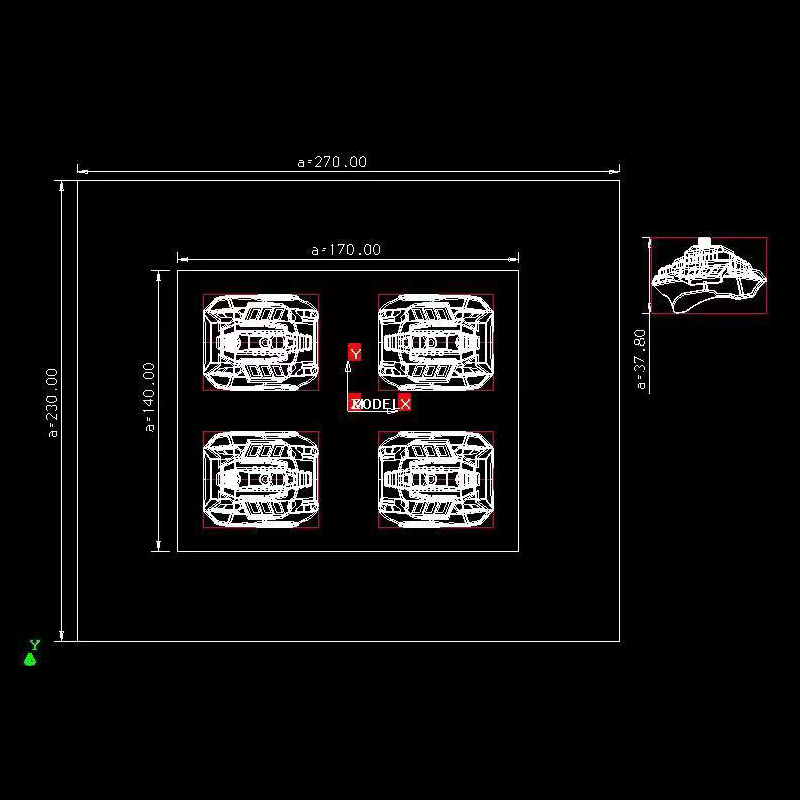

High-quality OEM plastic mould offer several advantages that are crucial for efficient and effective manufacturing processes. These mould are tailored specifically to meet the unique needs of original equipment manufacturers (OEMs), resulting in performance and product outcomes.

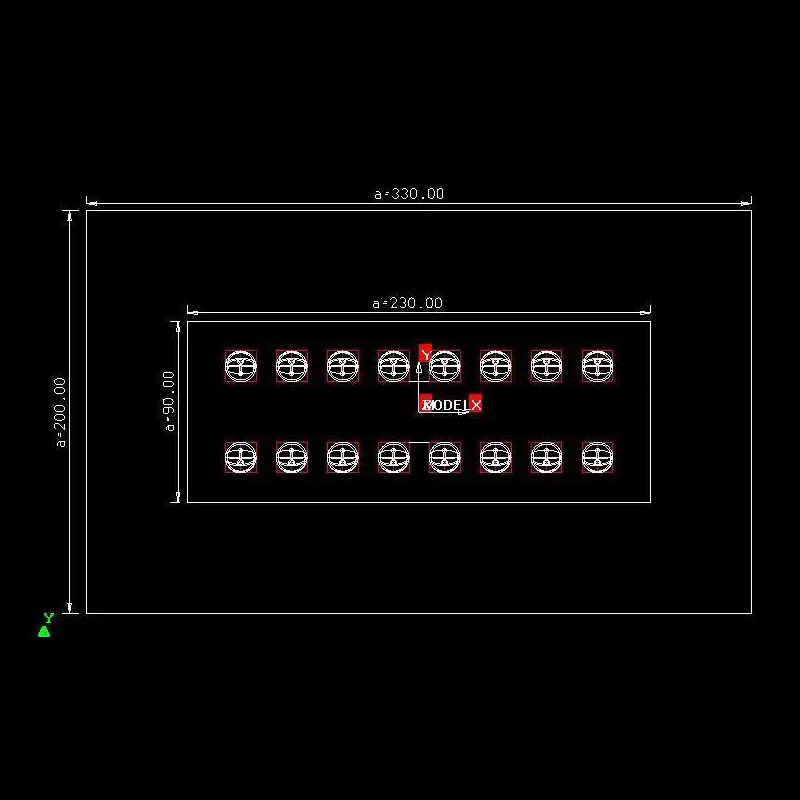

One of the primary benefits of high-quality OEM plastic mould is their precision. These mould are designed to exact specifications, ensuring that the produced parts or products meet stringent quality standards. This precision reduces the likelihood of defects and reduces the need for post-production adjustments, bringing about more consistent and reliable products.

Durability is another significant advantage of high-quality OEM plastic mould. Made from premium materials and crafted with advanced techniques, this mould can withstand the stresses of continuous production runs. This durability extends the lifespan of the mould and reduces the frequency of replacements, resulting in long-term cost savings for manufacturers.

High-quality OEM plastic mould also enhances production efficiency. Their design and construction facilitate smoother and faster production cycles, which can bring about higher output and reduced times. This efficiency is particularly important in competitive markets where time-to-market can impact a company's success.

Additionally, high-quality OEM plastic mould often comes with better support and service from the supplier. This support can include technical assistance, maintenance services, and troubleshooting, all of which contribute to maintaining mould performance and addressing any issues promptly.

High-quality OEM plastic mould provides precision, durability, efficiency, and valuable support. These advantages make them a wise investment for manufacturers seeking to achieve consistent and high-standard production results. By choosing high-quality mould, businesses can ensure that their manufacturing processes are both effective and sustainable.

English

English Español

Español عربى

عربى