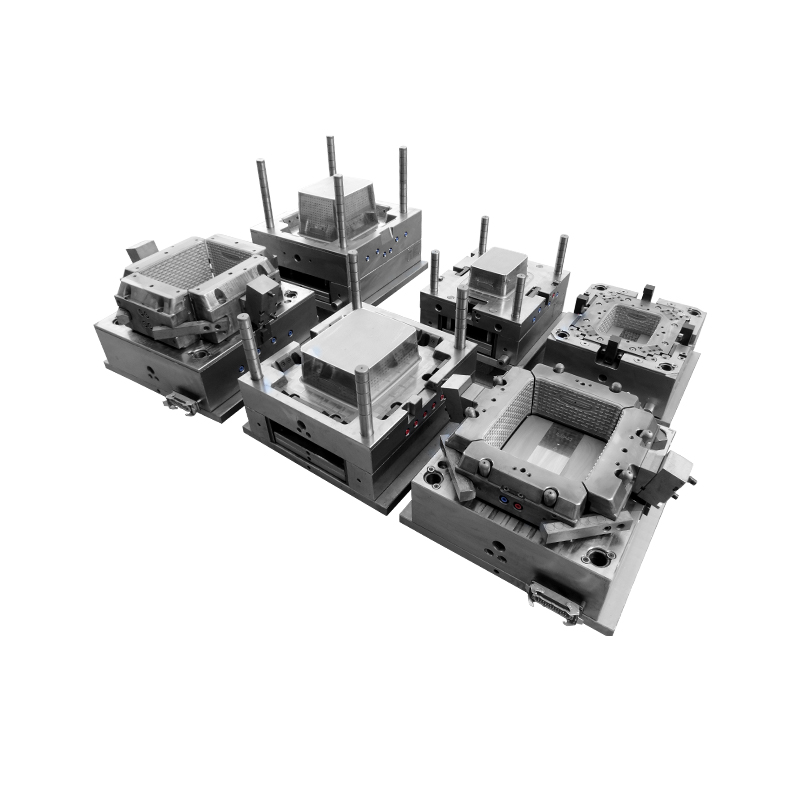

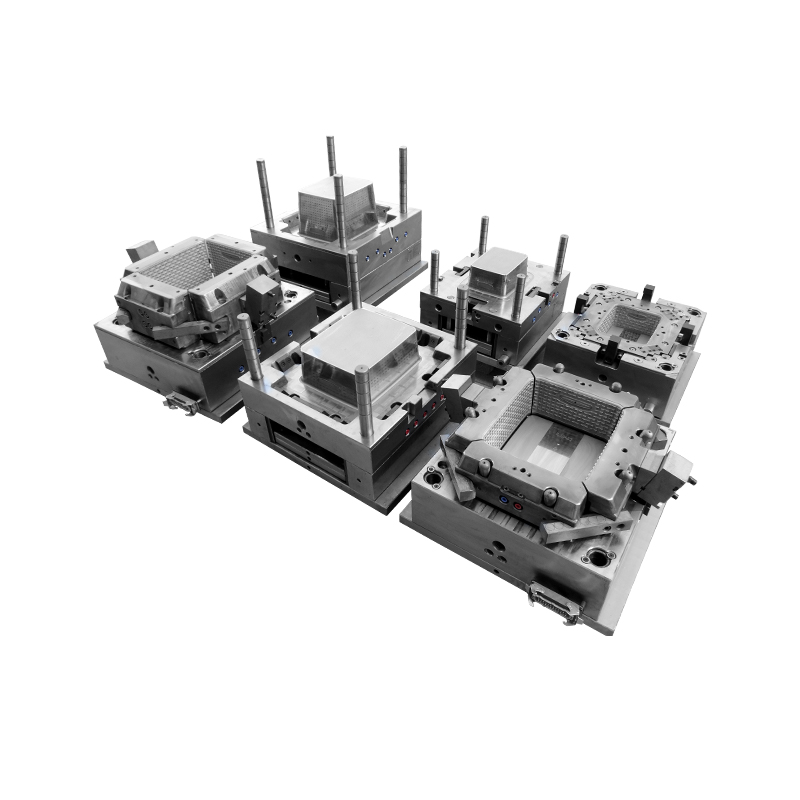

While the utilization of high transparent PP presents its own set of challenges, our mould design incorporates innovative solutions to mitigate potential issues. Product sticking, often encountered during the injection moulding process, is effectively addressed through strategic polishing techniques applied to the core's side walls. By optimizing surface smoothness, we eliminate friction points and ensure seamless product release, thereby enhancing overall productivity.

Furthermore, to augment the longevity and performance of our mould, meticulous attention is paid to post-production processes. Chrome coating of the core and cavity not only enhances durability but also mitigates wear and tear, prolonging the mould's lifespan and maintaining product quality over time. By investing in quality materials and precision craftsmanship, we uphold our commitment to delivering moulding solutions that exceed expectations.

The seamless integration of design elements ensures that our mould produces storage boxes that are not only functional but also visually stunning. Smooth surfaces, sharp edges, and consistent dimensions characterize every product, reflecting our unwavering dedication to quality and greatness. Whether it's a large storage container or a compact organizer, our mould delivers consistency in performance and aesthetics, setting a new standard in the industry.

With a steadfast commitment to quality and customer satisfaction, we continue to push the boundaries of greatness in mould design and manufacturing. Our mould stands as a testament to our dedication to innovation and our relentless pursuit of fineness. As we look towards the future, we remain committed to delivering cutting-edge solutions that empower our clients to achieve their goals efficiently and effectively.

English

English Español

Español عربى

عربى