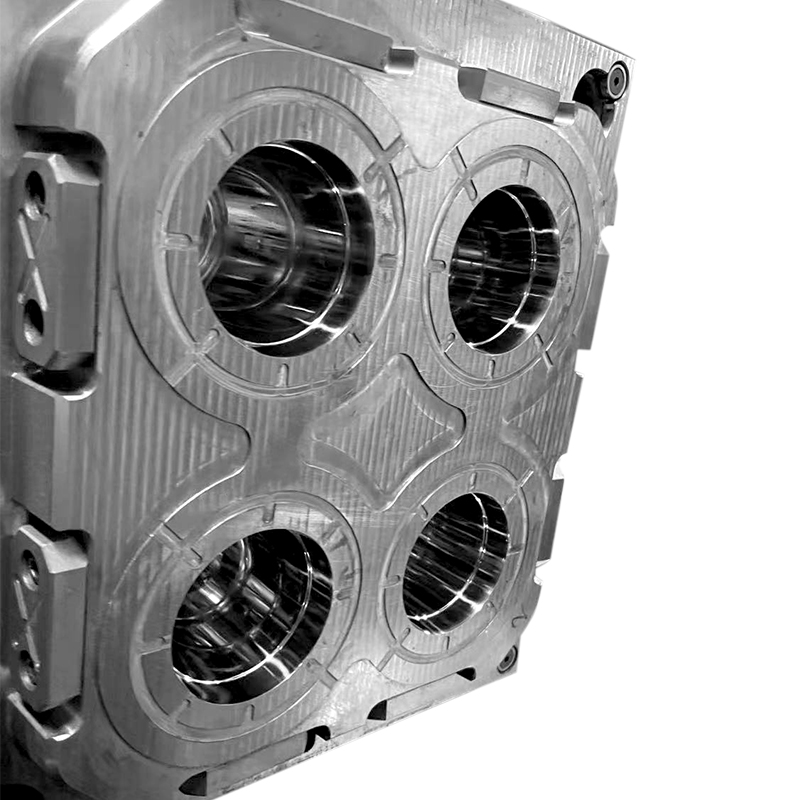

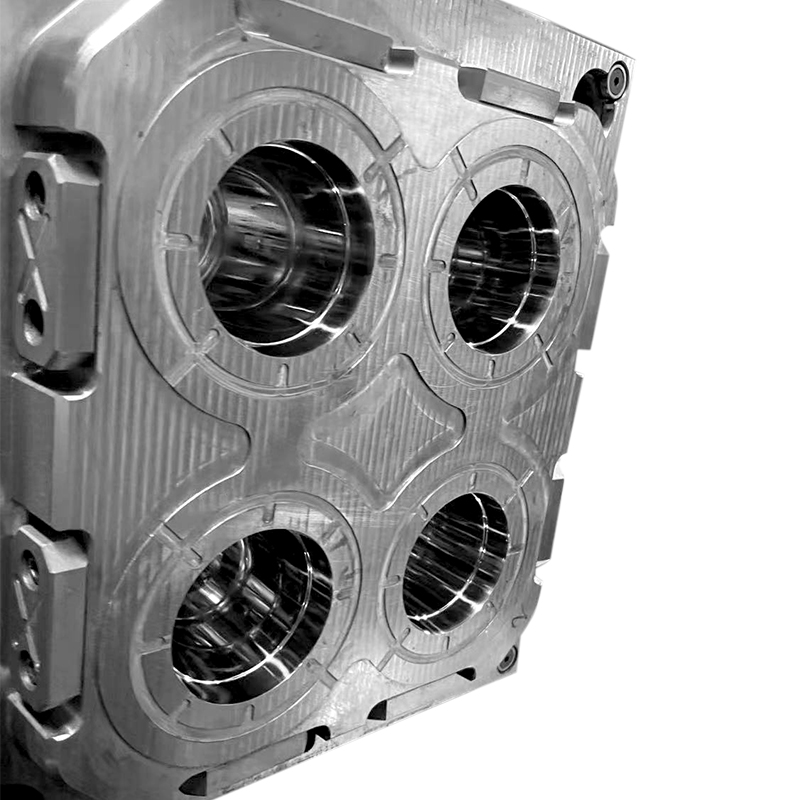

Customization Options:

One of the key features of our Plastic Injection Cup Moulds is their ability to accommodate a wide range of customization options. Whether it's adding handles, incorporating unique engraving designs, or choosing between textured or polished finishes, our molds can be tailored to meet specific requirements. Additionally, customers have the flexibility to opt for multi-cavity molds, allowing for increased production efficiency.

Material Selection:

We understand that different plastic materials offer varying properties and characteristics. Therefore, our Plastic Injection Cup Moulds are compatible with a variety of materials, including PP, PC, PS, and SAN. Depending on the desired outcome and application, customers can choose the suitable material for their cups.

Professional Guidance:

We recognize that navigating the complexities of Plastic Injection Cup Moulds can be challenging. That's why we offer our customers expert guidance and support throughout the entire process. From material selection to mold design and optimization, our team is committed to delivering comprehensive solutions that meet and exceed expectations.

In conclusion, our Plastic Injection Cup Moulds represent a solution of quality, versatility, and innovation. With a focus on customization, material compatibility, cooling and structure design, and professional guidance, we provide a comprehensive solution for all cup production needs. Partner with us and experience the difference that our Plastic Injection Cup Moulds can make in your business.

English

English Español

Español عربى

عربى